Product Series

QC11Y/K series CNC hydraulic guillotine shearing machine

Specializing in the production of "Teng" brand series of hydraulic shearing machine, mechanical shearing machine, hydraulic bending machine

Key words:

QC11Y/K series CNC hydraulic guillotine shearing machine

Product Details

Product Features:

Second Generation Hydraulic Shearing Machine

All-steel welded structure, heat treated to eliminate internal stress, with good rigidity and stability

Adopts an advanced integrated hydraulic system, high reliability

Adopts a three-point support rolling guide rail to eliminate support clearance and improve shearing quality

Blade gap adjusted by hand wheel, fast, accurate, and convenient

Rectangular blade, all four cutting edges can be used, long service life

Shear angle adjustable, reducing sheet metal distortion

The upper knife holder adopts an inward-inclined structure, which facilitates material dropping and improves the accuracy of the workpiece

It has a segmented shearing function and a light alignment function

Motorized back gauge, digital display

Back gauge device (optional)

Machine body

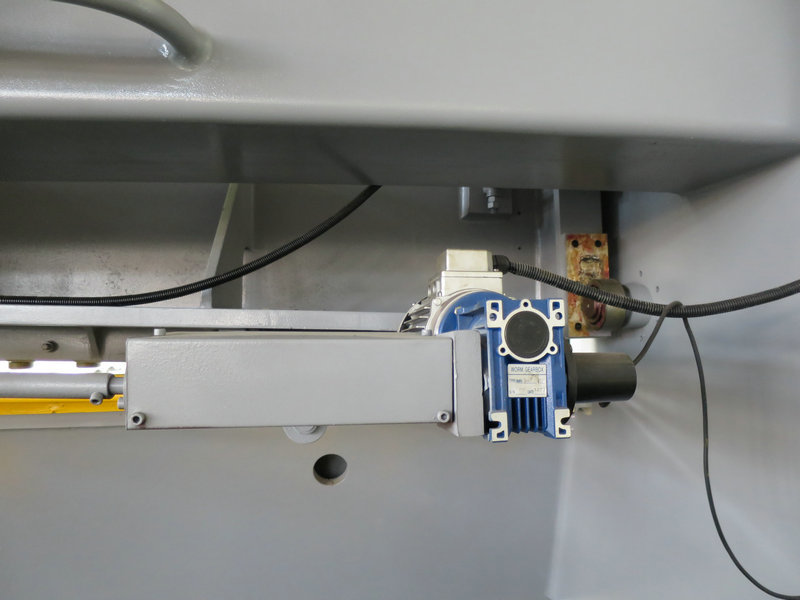

Back gauge and motor

Blade gap adjustment

HT21 CNC system, with built-in monitoring function, automatically memorizes the number of shearings, high shearing accuracy

Hydraulic system

1. Advanced integrated hydraulic system, reducing piping installation and ensuring high reliability and safety during machine operation

2. Clamping mechanism: After several clamping oil cylinders installed on the front support plate of the machine frame are oiled, the clamping head presses down after overcoming the pulling force of the tension spring to clamp the sheet metal. After shearing is completed, it is reset by the pulling force of the tension spring. The clamping force increases with the increase of the thickness of the sheet metal to be sheared. The adjustment of the back gauge is driven by a servo motor, and transmitted by a ball screw after gear reduction.

Guillotine Shear Parameters:

| Model |

Shearing thickness (mm) |

Shearing width (mm) |

Number of strokes (mm-1) |

Back gauge stroke (mm) |

Shearing angle (°) |

Worktable height (mm) |

Motor power (kw) |

| QC11Y-6x2500 |

6 |

2500 |

16~35 |

20-600 |

30′- 1°30 |

800 |

7.5 |

| QC11Y-6x3200 |

6 |

3200 |

14~35 |

20-600 |

30′- 1°30 |

800 |

7.5 |

| QC11Y-6x4000 |

6 |

4000 |

10~30 |

20-600 |

30′- 1°30 |

800 |

7.5 |

| QC11Y-6x5000 |

6 |

5000 |

10~30 |

20-800 |

30′- 1°30 |

900 |

11 |

| QC11Y-6x6000 |

6 |

6000 |

8~25 |

20-800 |

30′- 1°30 |

1000 |

11 |

| QC11Y-8x2500 |

8 |

2500 |

14~30 |

20-600 |

30′- 2° |

800 |

11 |

| QC11Y-8x3200 |

8 |

3200 |

12~30 |

20-600 |

30′- 2° |

850 |

11 |

| QC11Y-8x4000 |

8 |

4000 |

10~25 |

20-800 |

30′- 2° |

900 |

11 |

| QC11Y-8x5000 |

8 |

5000 |

10~25 |

20-800 |

30′- 2° |

1000 |

15 |

| QC11Y-8x6000 |

12 |

6000 |

8~20 |

20-800 |

30′- 2° |

1050 |

15 |

| QC11Y-12x2500 |

12 |

2500 |

12~25 |

20-800 |

30′- 2° |

840 |

15 |

| QC11Y-12x3200 |

12 |

3200 |

12~25 |

20-800 |

30′- 2° |

900 |

15 |

| QC11Y-12x4000 |

12 |

4000 |

8~20 |

20-800 |

30′- 2° |

940 |

15 |

| QC11Y-12x5000 |

12 |

5000 |

8~20 |

20-1000 |

30′- 2° |

1000 |

22 |

| QC11Y-12x6000 |

12 |

6000 |

6~20 |

20-1000 |

30′- 2° |

1060 |

30 |

| QC11Y-16x2500 |

16 |

2500 |

12~20 |

20-800 |

30′-1 °30 |

840 |

22 |

| QC11Y-16x3200 |

16 |

3200 |

12~20 |

20-800 |

30′- 1°30 |

900 |

22 |

| QC11Y-16x4000 |

16 |

4000 |

8~15 |

20-800 |

30′- 1°30 |

940 |

22 |

| QC11Y-16x5000 |

16 |

5000 |

8~15 |

20-1000 |

30′- 1°30 |

1000 |

30 |

| QC11Y-16x6000 |

16 |

6000 |

6~15 |

20-1000 |

30′- 1 °30 |

1100 |

37 |

| QC11Y-20x2500 |

20 |

2500 |

10~20 |

20-800 |

30′- 3° |

900 |

30 |

| QC11Y-20x3200 |

20 |

3200 |

10~20 |

20-800 |

30′- 3° |

950 |

30 |

| QC11Y-20x4000 |

20 |

4000 |

8~15 |

20-800 |

30′- 3° |

1100 |

30 |

| QC11Y-20x5000 |

20 |

5000 |

8~15 |

20-1000 |

30′- 3° |

1100 |

37 |

| QC11Y-20x6000 |

20 |

6000 |

6~15 |

20-1000 |

30′- 3° |

1200 |

37 |

| QC11Y-25x2500 |

25 |

2500 |

8~15 |

20-800 |

30′- 1°30 |

900 |

37 |

| QC11Y-25x3200 |

25 |

3200 |

8~15 |

20-800 |

30′- 1°30 |

950 |

37 |

| QC11Y-25x4000 |

25 |

4000 |

6~15 |

20-1000 |

30′- 1°30 |

1100 |

37 |

| QC11Y-32x2500 |

32 |

2500 |

6~15 |

20-1000 |

30′- 4° |

1000 |

55 |

| QC11Y-32x3200 |

32 |

3200 |

8~15 |

20-1000 |

30′- 4° |

1100 |

55 |

| QC11Y-40x2500 |

40 |

2500 |

4~10 |

20-1000 |

30′- 4° |

1200 |

55 |

| QC11Y-40x3200 |

40 |

3200 |

4~10 |

20-1000 |

30′- 4° |

1200 |

55 |

recommend products

Quick Links

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Contact Us

Address: Li Bao Town Industrial Park, Haian, Jiangsu

Service Hotline:+86 13962704913

WeChat ID: th19051399351

E-mail: sale01@nttzmt.com