Product Series

WC67K/Y series CNC (ordinary) hydraulic plate bending machine

Specializing in the production of "Teng" brand series of hydraulic shearing machine, mechanical shearing machine, hydraulic bending machine

Key words:

WC67K/Y series CNC (ordinary) hydraulic plate bending machine

Product Details

Features

●The mainframe adopts the WC67Y series hydraulic plate bending machine structure;

●The CNC system uses the DELEM dedicated bending machine CNC system;

●The back gauge and stroke adjustment motor use imported AC servo motors;

●The back gauge screw adopts imported ball screw + linear guide;

●Other models of CNC systems can be selected according to user needs;

Bending Machine Technical Parameters

| Specification Model | Nominal Pressure kN | Worktable Length mm | Distance between uprights mm | Throat Depth mm | Slide Stroke mm | Main Motor Power kW |

| WC67Y/K-40/2000 | 400 | 2000 | 1590 | 100 | 200 | 5.5 |

| WC67Y/K-40/2200 | 400 | 2200 | 1590 | 100 | 200 | 5.5 |

| WC67Y/K-40/2500 | 400 | 2500 | 2090 | 100 | 200 | 5.5 |

| WC67Y/K-50/2500 | 500 | 2500 | 1901 | 120 | 250 | 5.5 |

| WC67Y/K-50/3200 | 500 | 3200 | 2600 | 120 | 250 | 5.5 |

| WC67Y/K-63/2500 | 630 | 2500 | 2050 | 100 | 250 | 5.5 |

| WC67Y/K-63/3200 | 630 | 3200 | 2600 | 100 | 250 | 5.5 |

| WC67Y/K-80/3200 | 800 | 3200 | 2600 | 120 | 320 | 7.5 |

| WC67Y/K-80/4000 | 800 | 4000 | 3200 | 120 | 320 | 7.5 |

| WC67Y/K-100/2500 | 1000 | 2500 | 1900 | 120 | 320 | 7.5 |

| WC67Y/K-100/3200 | 1000 | 3200 | 2600 | 120 | 320 | 7.5 |

| WC67Y/K-100/4000 | 1000 | 4000 | 3200 | 120 | 320 | 7.5 |

| WC67Y/K-100/5000 | 1000 | 5000 | 4000 | 120 | 320 | 7.5 |

| WC67Y/K-125/2500 | 1250 | 2500 | 2050 | 120 | 320 | 7.5 |

| WC67Y/K-125/3200 | 1250 | 3200 | 2600 | 120 | 320 | 7.5 |

| WC67Y/K-125/4000 | 1250 | 4000 | 3200 | 120 | 320 | 7.5 |

| WC67Y/K-125/5000 | 1250 | 5000 | 4000 | 120 | 320 | 7.5 |

| WC67Y/K-160/3200 | 1600 | 3200 | 2600 | 200 | 320 | 11 |

| WC67Y/K-160/4000 | 1600 | 4000 | 3200 | 200 | 320 | 11 |

| WC67Y/K-160/5000 | 1600 | 5000 | 4000 | 200 | 320 | 11 |

| WC67Y/K-160/6000 | 1600 | 6000 | 4800 | 200 | 320 | 11 |

| WC67Y/K-200/3200 | 2000 | 3200 | 2600 | 200 | 320 | 15 |

| WC67Y/K-200/4000 | 2000 | 4000 | 3200 | 200 | 320 | 15 |

| WC67Y/K-200/5000 | 2000 | 5000 | 4000 | 200 | 320 | 15 |

| WC67Y/K-200/6000 | 2000 | 6000 | 4800 | 200 | 320 | 15 |

| WC67Y/K-250/3200 | 2500 | 3200 | 2600 | 200 | 400 | 18.5 |

| WC67Y/K-250/4000 | 2500 | 4000 | 3200 | 250 | 400 | 18.5 |

| WC67Y/K-250/5000 | 2500 | 5000 | 4000 | 250 | 400 | 18.5 |

| WC67Y/K-250/6000 | 2500 | 6000 | 4800 | 250 | 400 | 18.5 |

| WC67Y/K-300/3200 | 3000 | 3200 | 2600 | 250 | 400 | 22 |

| WC67Y/K-300/4000 | 3000 | 4000 | 3200 | 250 | 400 | 22 |

| WC67Y/K-300/5000 | 3000 | 5000 | 4000 | 250 | 400 | 22 |

| WC67Y/K-300/6000 | 3000 | 6000 | 4800 | 250 | 400 | 22 |

| WC67Y/K-400/4000 | 4000 | 4000 | 3200 | 320 | 400 | 22 |

| WC67Y/K-400/5000 | 4000 | 5000 | 4000 | 320 | 400 | 22 |

| WC67Y/K-400/6000 | 4000 | 6000 | 4800 | 320 | 400 | 22 |

| WC67Y/K-500/6000 | 5000 | 6000 | 4800 | 320 | 400 | 37 |

| WC67Y/K-600/7000 | 6000 | 7000 | 5600 | 320 | 400 | 37 |

| WC67Y/K-700/7000 | 7000 | 7000 | 5600 | 320 | 400 | 45 |

| WC67Y/K-800/6000 | 8000 | 6000 | 4800 | 400 | 500 | 55 |

| WC67Y/K-1000/6000 | 10000 | 6000 | 4800 | 400 | 600 | 75 |

Due to continuous product improvements, if there are inconsistencies between the sample technical data and the actual product data, the technical parameter agreement between the two parties shall prevail. No further notice will be given.

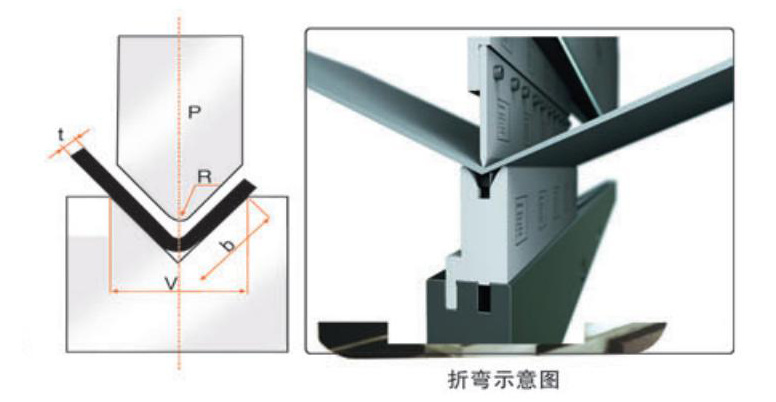

After determining the material thickness and the inner radius of the bend, please refer to the table below

1. The table shows the pressure required per meter when bending the material.

2. The V-groove width (V) of the lower die used during bending.

3. The shortest side length (b) obtained after bending.

Note: The table below shows the V-groove width of the die corresponding to the general plate thickness

recommend products

Quick Links

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Contact Us

Address: Li Bao Town Industrial Park, Haian, Jiangsu

Service Hotline:+86 13962704913

WeChat ID: th19051399351

E-mail: sale01@nttzmt.com