Structural Design of a New Bending Machine Base

Release time:

2020-12-22

This scheme is a new type of bending machine base, including a base, the left and right sides of the base are fixedly installed with side plates, the upper ends of the left and right side walls are fixedly installed with left and right blade guide grooves, and rollers are rotatably installed in the guide grooves. A groove is provided on the upper surface of the base.

This scheme is a new type of bending machine base, including a base. The left and right sides of the base are fixedly installed with side plates. The upper ends of the left and right side walls are fixedly installed with left and right blade guide grooves. Rollers are rotatably installed in the guide grooves, and a groove is provided on the upper surface of the base. This utility model has good bending effect, the blade is not easy to be damaged, and the blade is pressed smoothly.

1. The bending machine base includes a base, characterized in that: left and right side plates are fixedly installed on the left and right sides of the base; left and right blade guide grooves are fixedly installed on the upper ends of the left and right side plates; rollers are rotatably installed in the guide grooves; and a groove is provided on the upper surface of the base.

A pin is installed on the upper end of the left and right side plates, and a bearing installation groove is provided on the side wall of the pin.

Background Technology

In the prior art, the bending machine base has an unstable structure. During the pressing process of the blade, the blade is easily skewed, easily damaging the blade, and affecting the service life of the blade.

Utility Model Content

The purpose of the novel technology is to provide a bending machine base with good bending effect, blade is not easily damaged, and blade is pressed smoothly.

The novel solution to the technical problem is provided as follows:

A bending machine base, including a base, characterized in that: left and right side plates are fixedly installed on the left and right sides of the base; left and right blade guide grooves are fixedly installed on the upper ends of the left and right side plates; rollers are rotatably installed in the guide grooves; and a groove is provided on the upper surface of the base. Bearing installation grooves are provided on the side walls of the left and right pins. The blade guide grooves are fixedly installed on the upper ends of the left and right side plates of the base, and rollers are provided at the bottom of the guide grooves. In this way, when the blade is pressed down, the blade can maintain a vertical downward pressing direction, ensuring the service life of the blade and improving the bending efficiency.

Figure Description

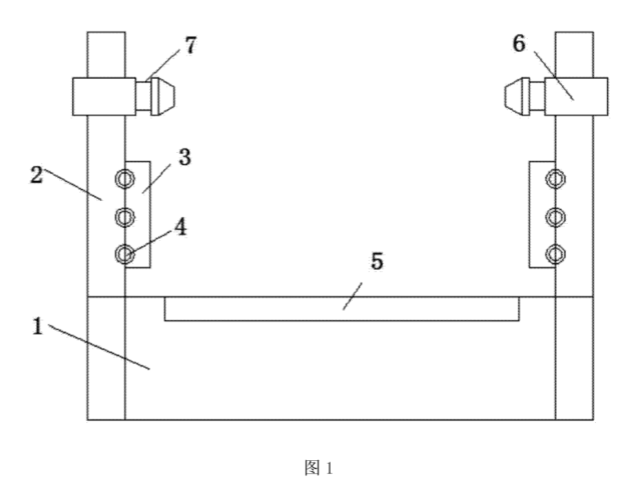

FIG. 1 is a structural diagram of the utility model.

Referring to the drawings, a bending machine base includes a base 1. Left and right side plates 2 are fixedly installed on the left and right sides of the base 1. Left and right blade guide grooves 3 are fixedly installed on the upper ends of the left and right side plates 2. Rollers 4 are rotatably installed in the guide grooves 3. A groove 5 is provided on the upper surface of the base 1. Pins 6 are installed on the upper ends of the left and right side plates 2, and bearing installation grooves 7 are provided on the side walls of the pins 6.

Referring to the accompanying drawings, a bending machine base includes a base, side plates 2 are fixedly installed on the left and right sides of the base 1, left and right blade guide grooves 3 are fixedly installed on the upper ends of the left and right side plates 2, rollers 4 are rotatably installed in the guide grooves 3, and a groove 5 is provided on the upper surface of the base 1. Pins 6 are installed on the upper ends of the left and right side plates 2, and bearing installation grooves 7 are provided on the side walls of the pins 6.

REAL-TIME NEWS

Quick Links

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Contact Us

Address: Li Bao Town Industrial Park, Haian, Jiangsu

Service Hotline:+86 13962704913

WeChat ID: th19051399351

E-mail: sale01@nttzmt.com